Choosing the correct twist for the industrial sewing thread used in your application is an important consideration in how smoothly your manufacturing process works. That is why it's important to know the difference between left twist and right twist industrial sewing threads.

Choosing the correct twist for the industrial sewing thread used in your application is an important consideration in how smoothly your manufacturing process works. That is why it's important to know the difference between left twist and right twist industrial sewing threads.

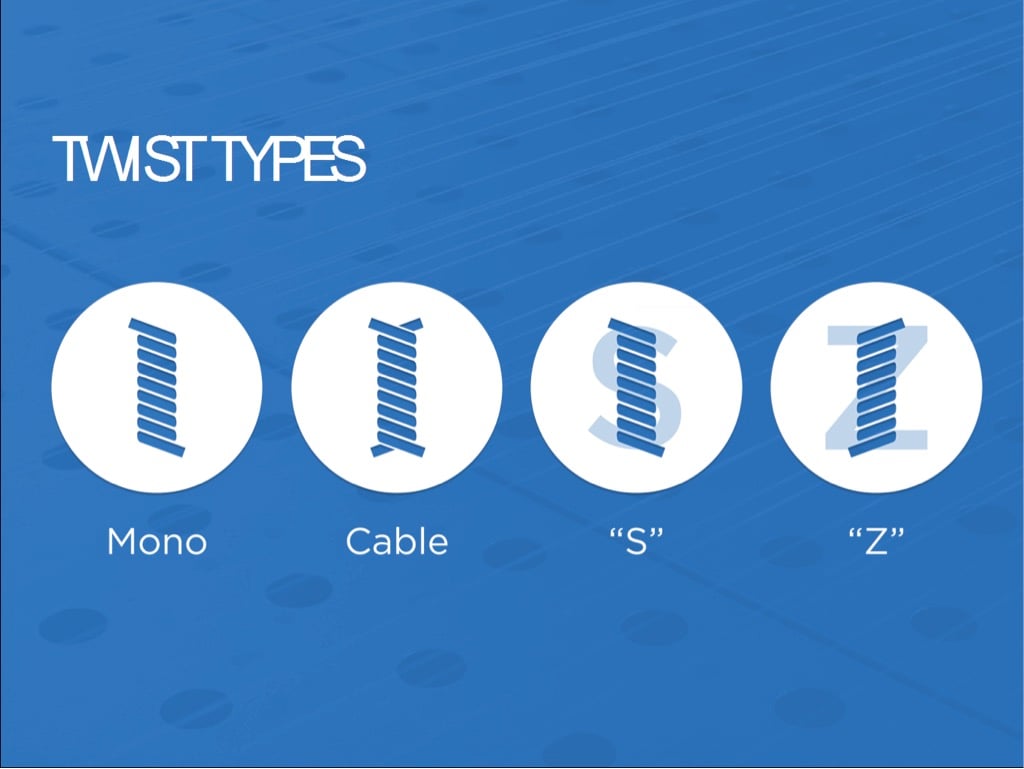

In order to understand twist and the correct application for each type, it may be helpful to first present an overview of the thread manufacturing process. Beginning with either short fibers or continuous filaments, fibers are twisted together to produce fine yarns. This is known as “singling twist” and is what gives thread its flexibility and strength. In order to balance threads when two or more plies, or individual threads, are combined to make the finished thread, a reverse twist is applied. Without this reverse twist, the yarn would separate into individual plies when used in sewing.

The process of sewing applies additional twist to the thread as it passes through the machine. Most sewing machines use a single needle; threads with a left twist, or Z-twist, are designed to pass through these needles with ease. The sewing process tends to increase the twist of this thread.

If threads with a right twist, or S-twist, are used in these single-needle machines, the sewing process can actually untwist these threads. The result is a snarled mess which puts a quick halt to the manufacturing process. S-twist threads are appropriate for use in double-needle machines engineered specifically for use with right twist threads.

The direction of a thread's twist doesn't affect its strength, but it will seriously impair the thread's performance when it is used on an unsuitable machine. For that reason, it is important to choose a thread that was designed and engineered for use on your particular machines.

Do you need help determining the right industrial sewing thread for your application? Contact us today!